LTP Precision | PO Box 728 | 17763 State Highway 198 | Saegertown, PA 16433 (814) 763-2032 requestinfo@ltpprecision.com

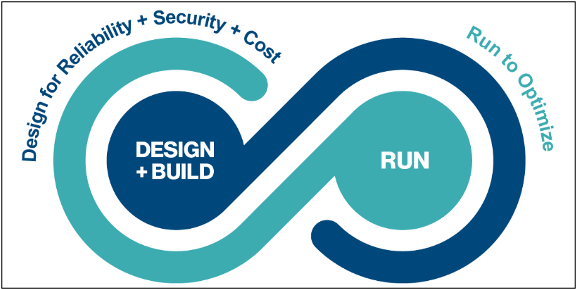

LTP Precision prides themselves in their capability to Design, Build, and Run with a knowledgeable staff that at its core of employees has over 100 years of combined experience and expertise. LTP’s in house “Design” engineers solve problems and excel in part and tool development to customers specifications and standards. On the “Build” side, or tooling, their tool makers and machinists build high quality plastic injection molds including multi-cavity molds for a wide range of industries varying from medical to commercial and residential use. We specialize in hot runner systems for both proprietary and leading brands across the industries we serve. The production or “Run” end of the business is dedicated to maximizing productivity and efficiency with small to medium size plastic parts that include secondary operations and proper assembly, packaging, and shipping of these products for on-time delivery.

To complement this, we have suppliers capable of delivering exotic metals and high engineered plastics.

LTP Precision is a proud member of the NWPA NTMA. The NTMA provides us with 500 professionals to assist us in providing you high quality secondary operations such as vacuum heat treating, multiple types of plating, polishers, precision welders, etching, engraving, and more.